Wire harness design is often treated as a production afterthought, leading to complexity, delays, and errors. Re:Build solves this head-on with an end-to-end approach. Our capabilities span the entire product lifecycle, from initial concept and detailed electrical design to high-volume manufacturing and testing. We specialize in creating custom wire harnesses and cable assemblies that meet precise technical specifications, ensuring seamless integration and optimal performance for your innovative application.

Whether you are launching an innovative product or optimizing for scale, our end-to-end wire harness execution process is engineered to deliver optimal design, technical manufacturing precision, and speed-to-market. From product development through continuous improvement our manufacturability for design (MFD) process ensures you accelerate with unmatched efficiency with built-in early manufacturability insights.

At Re:Build Manufacturing, we deliver more than wire harnesses, we deliver confidence. With decades of experience across innovative industries, we have the deep technical expertise required to deliver harness solutions that combine precision engineering, agile co-development, and a relentless commitment to quality.

We offer reliable wiring solutions designed to handle the unique challenges of the transportation industry, from automotive and railway to heavy equipment.

We offer reliable wiring solutions designed to handle the unique challenges of the transportation industry, from automotive and railway to heavy equipment.

Our robust harnesses are engineered to withstand harsh environments, powering the complex robotics, machinery, and control systems of industrial automation.

We design and build custom harnesses that power the precise motion and complex control systems in robotics and automation equipment.

We create high-precision cables for diagnostic equipment, patient monitoring, and surgical devices that meet the rigorous standards of the medical field.

Our team is ready to support you. Whether you’re looking to explore custom solutions, address specific project requirements, or gain a deeper understanding of our capabilities, we’re here to help.

We offer transformative wire harness capabilities, with cloud-based software, expert design engineering, and precision manufacturing in one ecosystem. We are accelerating time-to-market by reducing lead-times from weeks to days. We excel at digital design, deep expertise in embedded systems, and manufacturing production. This synergy provides an end-to-end platform from concept to production, making us the ideal partner for companies creating the next generation of complex electrical systems.

Arcadia by Re:Build Cadonix is a comprehensive, cloud-based software suite that streamlines the entire wire harness design and manufacturing process. Our platform eliminates errors and dramatically accelerates time-to-market by automating complex tasks, from schematic design to final production.

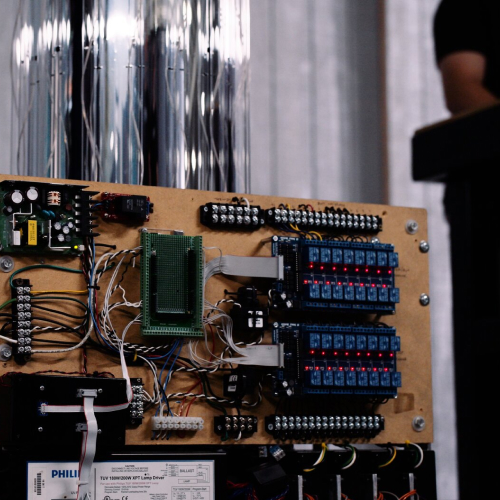

Our embedded systems and FPGA development expertise transforms requirements into a functional design. We specialize in designing and integrating advanced system architectures, from sensors to actuators, to enable precise automation for intelligent machines. Our experience also includes safety-critical design, ensuring systems adhere to rigorous standards for demanding, high-risk environments.

We use automated and semi-automated equipment to ensure precision and consistency. Our capabilities include precise wire stripping, crimping, marking, and thorough testing. These capabilities are supported by advanced tools that improve consistency, reduce lead times, and ensure results that comply with customer requirements.

Our team is ready to support you, so please reach out to discuss your specific needs or to learn more about our comprehensive wire harness capabilities.